GUARDENT, A high quality heat resistant safety sheet vinyl for outdoor/indoor use.

NS550 GARDENT is a non-slip vinyl A high quality heat resistant safety sheet vinyl for outdoor/indoor use. NS550 GARDENT has excellent weather-resistance and high durability. Available in10 Vivid colours are available.

Benefits:

Features:

Stock Situation:

Suitable For: Poolside applications, both indoor and outdoor

Item of interest: (poolside-vinyl), Aquatread NS550 Safety

Required fields are followed by *.

Enter in the measurements of your room

Code: poolside-vinyl

Poolside Safety Vinyl | NS551 & NS555

Poolside Safety Vinyl | NS551 & NNS555

Poolside Safety Vinyl | NS560

Results of improvement (dB)

Measurement:

Using a tone generator below, noise is measured by a sound level noise meter able to detect 1000Hz single note of a manually created shock.

Reduction of each floor type:

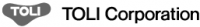

Weather Resistance

Alteration or discoloration of resilient flooring will occur if exposed to direct sunlight. Where resilient flooring is exposed to the effects of large amounts of UV, a strong reaction to ultraviolet radiation, will accelerate fading dye pigments a normal chemical reaction to UV.

In the case of indoor, the use of light shielding window treatments such as blinds, curtains, window tinting will help to reduce the effectives of ultraviolet rays. In the absence of window treatments, such as open hallways and pools, places that are exposed to direct sunlight, weather resistance with excellent flooring material is required.

NS Real, NS800, NS9500, NS500 safety flooring are all weather tested using Test method

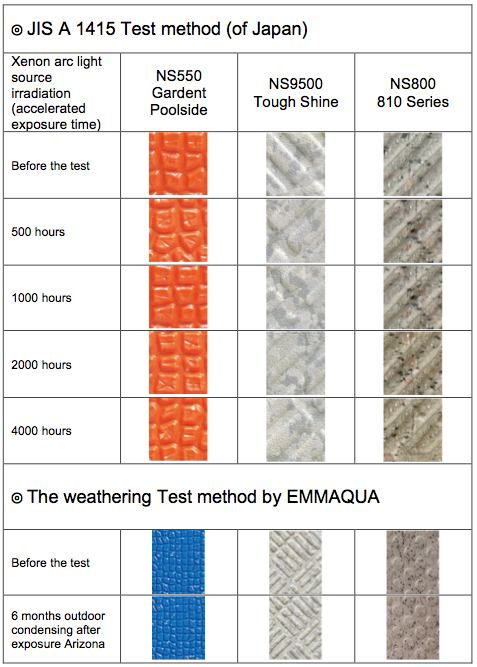

◎ JIS A 1415 Test method (of Japan)

"Exposure test by 6.1 xenon arc light source exposure testing method according to laboratory light source of polymer-based building materials" JIS A 1415. (: 63 ± 3 ° C black panel temperature, irradiation after 102 minutes spray cycle, water spray and 18 minutes irradiation 7350-2 JIS K) implementing the exposure test using a xenon arc light source. – Product complies.

Method - The appearance changes of colour when exposure between 4000 hours is observed. The amount of discoloration is measured using the gray scale, which determines if the performance is a pass or higher.

◎ The weathering Test method by EMMAQUA

Using an accelerated test by EMMAQUA method as specified in ASTM G90 (Phoenix, Arizona, USA) simulates exposure to outdoors.

Using the virtual parabolic reflective solar tracking method, which uses a condensing device constituted by flat surface, mirrored over 10 sheets. By condensing the natural sunlight - coupons were attached to the target plate.

While maintaining the UV spectral balance of natural sunlight, NS Real, NS800, NS9500, NS500 safety flooring are irradiated with light intensity of approximately 8 times that of the sun. After six months of exposure, the test method then requires the observed the change in appearance to be measured.